Stainless Steel 904L Flanges

- Home

- Stainless Steel 904L Flanges

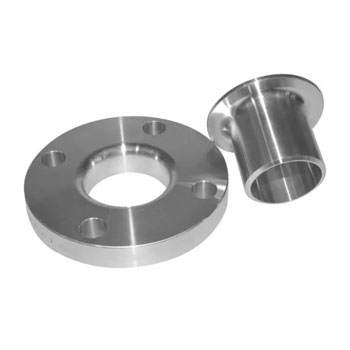

904L Stainless Steel Flanges, SS 904L Pipe Flange, 904L Stainless Steel Blind Flange, Stainless Steel 904L Flange, ASTM A182 Stainless Steel F904L Slip On Flanges at Best Price in India.

VM Energy Solutions INC is a known exporter and distributor of SS 904L Pipe Flanges, which exhibits higher corrosion resistance, and so it is tougher steel with an extended stringy chip, wherein the usage of chip breakers is recommended. Stainless Steel UNS N08904 Slip On Flanges is Non Magnetic and used while each the properties of steel and proof against corrosion are required, in which the excessive carbon can also additionally purpose strain corrosion cracking, mainly after welding thicker material. For heat treatment, it must be soaked at 1038 Degree C (1900 Degree F) for 30 min and cooled beneath Sixteen Degree C (60 Degree F) for complete martensitic transformation. It may be welded via way of means of not unusual fusion and resistance strategies; however, this steel ought to now no longer be joined the use of oxyacetylene welding method.

- Stainless Steel 904L Flanges Standard Specification

- Stainless Steel 904L Flanges Standard

- Stainless Steel 904L Flanges International Standards

- Different Forms of 904L Stainless Steel Flanges

- Stainless Steel 904L Flanges Chemical Composition

- 904L Stainless Steel Flanges Mechanical Properties

- Size Chart Of Stainless Steel 904L Flange

- Weight Chart Of Stainless Steel 904L Flanges

- Largest Inventory Of Stainless Steel 904L Flanges

- Manufacturing Standard / Pressure Rating of 904L SS Pipe Flanges

Lower carbon on these Stainless Steel WNR 1.4539 Socket Weld Flanges minimizes chromium carbide precipitation because of welding and its susceptibility to inter-granular corrosion. It has extraordinary toughness, even right all the way down to cryogenic temperatures which can be described as very low temperatures, and so it is as well utilized in moisture separator re-heaters, feed-water tubes, stator bars, heat exchangers, and so on. The balanced austenitic shape of this steel permits it to be seriously deep drawn without intermediate annealing, which has made this grade dominant within the manufacture of drawn stainless components which include sinks, hollow-ware and saucepans.

Stainless Steel 410 Plate Flange, ASTM A182 SS 904L Socket weld Flanges, ANSI B16.5 SS 904L Forged Flanges, SS 904L Slip on Flange, UNS N08904 Lap Joint Flanges, Stainless Steel 904L Weld Neck Flanges, DIN 1.4539 Industrial Flanges Supplier in Mumbai, India.

The addition of molybdenum and barely better nickel content material make these Alloy 904L Forged Flanges appropriate for architectural applications in extreme settings, from polluted marine environments to regions with sub-zero temperatures. Like different grades of steel, it is an especially bad conductor of both heat and of strength whilst as in comparison to metals and different conductive materials. It is simply brake or roll formed into lots of elements for applications within the industrial, architectural, and transportation fields. It is utilized in food industries, chemical industries, electric industries, generator industries, shaft industries, cement industries, gas industries, strength project, and so on.

We Keep Bulk Stock Of UNS N08904 WNRF Flanges, 410 Stainless Steel Long Weld Neck Flanges at Our Stockyard, Check SS 410 RTJ Flanges Dimension, Buy SS 410 Plate Flanges at an Affordable Price In India.

Stainless Steel 904L Flanges Standard Specification

| Size Chart | 1/2″ (15 NB) to 48″ (1200 NB) DN10~DN5000 |

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1BRaw Materials Certificate100% Radiography Test ReportThird Party Inspection Report, etc |

| Production technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawingAS, ANSI, BS, DIN and JIS15 NB (1/2″) to 200 NB (8″)Equal and Reducing Configurations |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI ultrasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. B.S: BS4504 , BS3293, BS1560, BS10 The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Stainless Steel 904L Flanges Standard

| American Steel Flanges Standard | |

| Standard Code | Standard Name |

| ANSI ASME SA-182 | Forged Flanges |

| ANSI ASME B16.5 | Slip on flange, Welding neck flange, Blind flange, Threaded flange, Lap joint flange, RTJ flange |

| ASME – B 16.47 | Welding neck flange, Blind flange |

| ASME – B 16.36 | Welding neck flange Slip on flange |

| German Steel Flanges Standard | |

| DIN 2527 | Steel Blind Flanges, BLRF |

| DIN 2573 / 2576 | Flat Flange for Welding (Slip On) |

| DIN 2673 | Loose Flanges and Rings for Welding (Slip On Flanges and Plain Collars) |

| DIN 2641 / 2642 | Lapped / Loose (Lap Joint) Flanges Plain Collars |

| DIN 28115 | Long Neck Welding Flanges |

| DIN PN10, PN16 | PN10 Flanges, DIN PN 10 Flanges, PN16 Flange |

| DIN PN20, PN25 | PN20 Flanges, DIN PN 25 Flanges |

| DIN PN40, PN50 | PN40 Flanges, DIN PN 50 Flanges |

| Japanese Steel Flanges Standard | |

| JIS B2220 | Slip On plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lap Joint (LJ), Threaded flange (TR)/ Integral flange (IT) Blank flange (BL) |

| JIS B2291 | Slip On plate flange (SOP), Slipon Hub (SOH), Socket Welding flange (SW), Welding neck flange (WN), Lap Joint (LJ), Threaded flange (TR)/ Integral flange (IT) Blank flange (BL) |

| JIS 5K, 10K | 5K SORF Flanges, 10K SOFF Flanges |

| JIS 16K, 20K | 16K Blind Flanges, 20K BLRF Flanges |

| JIS 30K, 40K | 30K Slip on Flanges, 40K Blind Flanges |

| Italian Flanges Standard | |

| UNI FLANGES | Plan flanges (2276, 2277, 2278, 6083, 6084) Welding neck (2280, 2281, 2282, 2283, 2284, 2285, 2286) Lapped flanges (6088, 6089, 6090, 2999, 2300) Blind flanges (6091, 6092, 6093, 6094, 6095, 6096, 6097) threaded flanges (2253, 2254) |

| British Standard Pipe Flanges Standard | |

| BS 10 Table D | BS 10 Table D Flanges, Table D Pipe Flange |

| BS 10 Table E | BS 10 Table E Flanges, Table E Pipe Flange |

| BS 10 Table F | BS 10 Table E Flanges, Table E Flanges |

| BS 10 Table H | BS 10 Table E Flanges, Table E Pipe Flanges |

Stainless Steel 904L Flanges International Standards

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | 03Х18Н11 | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Different Forms of 904L Stainless Steel Flanges

SS 904L Slip on Flanges

SS 904L RTJ Flanges

SS 904L Blind Flanges

SS 904L Weld Neck Flanges

SS 904L Lap Joint Flanges

SS 904L Threaded Flanges

SS 904L Socket weld Flanges

SS 904L Spectacle Blind Flanges

SS 904L Long Weld Neck Flanges

Stainless Steel 904L Flanges Chemical Composition

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | 03Х18Н11 | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

904L Stainless Steel Flanges Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.95 g/cm3 | 1350 °C (2460 °F) | Psi – 71000 , MPa – 490 | Psi – 32000 , MPa – 220 | 35 % |

Sing Patare

Size Chart Of Stainless Steel 904L Flange

| Normal Pipe Size | Flanges Diameter ('O') |

Diameter of (B.C.) 'A' |

Diameter of (B.H.) 'D' |

Holes Number |

Flanges Wall Thickness 'C' |

Diameter (Flanges) at Weld Bevel | (Flanges) Diameter of Hub 'E' |

Length Of Through Hub | Bore ('B') | Diameter of (RF) R |

Depth of Socket Weld F |

Threading Length |

||||

| SORF/ SWRF (Y) |

WNRF (Y) |

Lap Joit (Y) |

SORF/ SWRF (B) |

Lap Joit (B) |

||||||||||||

| 1/2'' | 15 | 95.2 | 66.7 | 15.9 | 4 | 14.3 | 21.3 | 38.1 | 22.2 | 52.4 | 22.2 | 22.3 | 22.9 | 34.9 | 9.5 | 15.9 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/4'' | 20 | 117.5 | 82.5 | 19.0 | 4 | 15.9 | 26.7 | 47.6 | 25.4 | 57.1 | 25.4 | 27.7 | 28.2 | 42.9 | 11.1 | 15.9 |

| 1'' | 25 | 123.8 | 88.9 | 19.0 | 4 | 17.5 | 33.5 | 54.0 | 27.0 | 61.9 | 27.0 | 34.5 | 35.0 | 50.8 | 12.7 | 17.5 |

| 1 | 32 | 133.3 | 98.4 | 19.0 | 4 | 20.6 | 42.2 | 63.5 | 28.6 | 66.7 | 28.6 | 43.2 | 43.7 | 63.5 | 14.3 | 20.6 |

| 1 | 40 | 155.6 | 114.3 | 22.2 | 4 | 22.2 | 48.3 | 69.8 | 31.7 | 69.8 | 31.7 | 49.5 | 50.0 | 73.0 | 15.9 | 22.2 |

| 2'' | 50 | 165.1 | 127.0 | 19.0 | 8 | 25.4 | 60.4 | 84.1 | 36.5 | 73.0 | 36.5 | 62.0 | 62.5 | 92.1 | 17.5 | 25.4 |

| 2 | 65 | 190.5 | 149.2 | 22.2 | 8 | 28.6 | 73.1 | 100.0 | 41.3 | 79.4 | 41.3 | 74.7 | 75.4 | 104.8 | 19.0 | 28.6 |

| 3'' | 80 | 209.5 | 168.3 | 22.2 | 8 | 31.8 | 88.9 | 117.5 | 46.0 | 82.5 | 46.0 | 90.7 | 91.4 | 127.0 | - | 30.2 |

| 3 | 90 | 228.5 | 184.2 | 22.2 | 8 | 34.9 | 101.6 | 133.4 | 49.3 | 85.7 | 49.3 | 103.4 | 104.1 | 140.0 | - | 31.7 |

| 4'' | 100 | 273.0 | 215.9 | 25.4 | 8 | 38.1 | 114.3 | 152.4 | 54.0 | 101.6 | 54.0 | 116.1 | 116.8 | 157.2 | - | 33.3 |

| 5'' | 125 | 330.2 | 266.7 | 28.6 | 8 | 44.4 | 141.2 | 188.9 | 60.3 | 114.3 | 60.3 | 143.8 | 144.5 | 185.7 | - | 36.5 |

| 6'' | 150 | 355.6 | 292.1 | 28.6 | 12 | 47.6 | 168.4 | 222.2 | 66.7 | 117.5 | 66.7 | 170.7 | 171.4 | 215.9 | - | 39.7 |

| 8'' | 200 | 419.1 | 349.2 | 31.7 | 12 | 55.6 | 219.2 | 273.0 | 76.2 | 133.3 | 76.2 | 221.5 | 222.2 | 269.9 | - | 44.4 |

| 10'' | 250 | 508.0 | 431.8 | 34.9 | 16 | 63.5 | 273.0 | 342.9 | 85.7 | 152.4 | 111.2 | 276.3 | 277.4 | 323.8 | - | 49.2 |

| 12'' | 300 | 558.8 | 488.9 | 34.9 | 20 | 66.7 | 323.8 | 400.0 | 92.1 | 155.6 | 117.3 | 327.1 | 328.2 | 381.0 | - | 55.6 |

| 14'' | 350 | 603.2 | 527.0 | 38.1 | 20 | 69.9 | 355.6 | 431.8 | 93.7 | 165.1 | 127.0 | 359.1 | 360.2 | 412.7 | - | 57.1 |

| 16'' | 400 | 685.8 | 603.2 | 41.3 | 20 | 76.2 | 406.4 | 495.3 | 106.4 | 177.8 | 139.7 | 410.5 | 411.2 | 469.9 | - | 63.5 |

| 18'' | 450 | 742.9 | 654.0 | 44.4 | 24 | 82.6 | 457.2 | 546.1 | 117.5 | 184.1 | 152.4 | 461.8 | 462.3 | 533.4 | - | 68.3 |

| 20'' | 500 | 812.8 | 723.9 | 44.4 | 24 | 88.9 | 508.0 | 609.6 | 127.0 | 190.5 | 165.1 | 513.1 | 514.3 | 584.2 | - | 73.0 |

| 24'' | 600 | 939.8 | 838.2 | 50.8 | 24 | 101.6 | 609.6 | 717.5 | 139.7 | 203.2 | 184.1 | 615.9 | 615.9 | 692.1 | - | 82.5 |

Weight Chart Of Stainless Steel 904L Flanges

| Pressure Class | Nominal Size Of Pipe (NPS) In Inch | Slip On (SORF) In Inch | Threaded (NPT) In Inch | Socket Weld (SWRF) In Inch | Lap Joint (LOOSE) In Inch | Blind (BLRF) In Inch | Weld Neck (WNRF) In Inch |

|---|---|---|---|---|---|---|---|

| Class 150 Flanges | ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 | |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 | |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 | |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 | |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 | |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 | |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 | |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 | |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 | |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 | |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 | |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 | |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 | |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 | |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 | |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 | |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 300 Flanges | ½ | 2 | 2 | 3 | 2 | 2 | 2 |

| ¾ | 3 | 3 | 3 | 3 | 3 | 3 | |

| 1 | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1¼ | 4.5 | 4.5 | 4 | 4.5 | 6 | 5 | |

| 1½ | 6.5 | 6.5 | 6 | 6.5 | 7 | 7 | |

| 2 | 7 | 7 | 7 | 7 | 8 | 9 | |

| 2½ | 10 | 10 | 10 | 10 | 12 | 12 | |

| 3 | 13 | 14 | 13 | 14.5 | 16 | 18 | |

| 3½ | 17 | 17 | 17 | 17 | 21 | 20 | |

| 4 | 23.5 | 24 | 22 | 24 | 28 | 26.5 | |

| 5 | 29 | 31 | 28 | 28 | 37 | 36 | |

| 6 | 39 | 39 | 39 | 39 | 50 | 45 | |

| 8 | 58 | 58 | 58 | 58 | 81 | 69 | |

| 10 | 81 | 81 | 81 | 91 | 124 | 100 | |

| 12 | 115 | 115 | 115 | 140 | 185 | 142 | |

| 14 | 165 | 165 | 165 | 190 | 250 | 206 | |

| 16 | 210 | 220 | 190 | 234 | 315 | 250 | |

| 18 | 253 | 280 | 250 | 305 | 414 | 320 | |

| 20 | 315 | 325 | 315 | 375 | 515 | 400 | |

| 22 | 370 | 370 | 370 | 435 | 640 | 465 | |

| 24 | 490 | 490 | 475 | 550 | 800 | 580 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 400 Flanges | ½ | 2 | 2 | 2 | 2 | 2 | 3 |

| ¾ | 3 | 3 | 3 | 3 | 3 | 3.5 | |

| 1 | 3.5 | 3.5 | 3.5 | 3.5 | 4 | 4 | |

| 1¼ | 4.5 | 4.5 | 4.5 | 4.5 | 6 | 4.5 | |

| 1½ | 6.5 | 6.5 | 6.5 | 6.5 | 8 | 8 | |

| 2 | 8 | 8 | 8 | 8 | 10 | 10 | |

| 2½ | 12 | 12 | 12 | 11 | 15 | 14 | |

| 3 | 15 | 15 | 15 | 14 | 20 | 18 | |

| 3½ | 21 | 21 | 21 | 20 | 29 | 26 | |

| 4 | 26 | 26 | 26 | 25 | 33 | 35 | |

| 5 | 31 | 31 | 31 | 29 | 44 | 43 | |

| 6 | 44 | 44 | 44 | 42 | 61 | 57 | |

| 8 | 67 | 67 | 67 | 64 | 100 | 89 | |

| 10 | 91 | 91 | 91 | 110 | 155 | 125 | |

| 12 | 130 | 130 | 130 | 152 | 226 | 175 | |

| 14 | 191 | 191 | 191 | 210 | 310 | 233 | |

| 16 | 253 | 253 | 253 | 280 | 398 | 295 | |

| 18 nbsp; | 310 | 310 | 310 | 345 | 502 | 360 | |

| 20 | 378 | 378 | 378 | 420 | 621 | 445 | |

| 22 | 405 | 405 | 405 | 455 | 720 | 505 | |

| 24 | 539 | 539 | 539 | 615 | 936 | 640 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 600 Flanges | ½ | 2 | 2 | 2 | 2 | 3 | 3 |

| ¾ | 3 | 3 | 3 | 3 | 4 | 4 | |

| 1 | 4 | 4 | 4 | 4 | 4 | 4 | |

| 1¼ | 5 | 5 | 5 | 5 | 6 | 6 | |

| 1½ | 7 | 7 | 7 | 7 | 8 | 8 | |

| 2 | 9 | 9 | 9 | 9 | 10 | 12 | |

| 2½ | 13 | 13 | 13 | 12 | 15 | 18 | |

| 3 | 16 | 16 | 16 | 15 | 20 | 23 | |

| 3½ | 21 | 21 | 21 | 20 | 29 | 26 | |

| 4 | 37 | 37 | 37 | 36 | 41 | 42 | |

| 5 | 63 | 63 | 63 | 63 | 68 | 68 | |

| 6 | 80 | 80 | 80 | 78 | 86 | 81 | |

| 8 | 115 | 15 | 15 | 112 | 140 | 120 | |

| 10 | 177 | 177 | 177 | 195 | 231 | 190 | |

| 12 | 215 | 215 | 215 | 240 | 295 | 226 | |

| 14 | 259 | 259 | 259 | 290 | 378 | 410 | |

| 16 | 366 | 366 | 366 | 400 | 527 | 481 | |

| 18 | 476 | 476 | 476 | 469 | 665 | 555 | |

| 20 | 612 | 612 | 612 | 604 | 855 | 690 | |

| 22 | 590 | 590 | 590 | 670 | 1000 | 720 | |

| 24 | 876 | 876 | 876 | 866 | 1250 | 977 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 900 Flanges | ½ | 6 | 6 | 6 | 6 | 4 | 7 |

| ¾ | 6 | 6 | 6 | 6 | 6 | 7 | |

| 1 | 7.5 | 7.5 | 7.5 | 7.5 | 9 | 8.5 | |

| 1¼ | 10 | 10 | 10 | 10 | 10 | 10 | |

| 1½ | 14 | 14 | 14 | 14 | 14 | 14 | |

| 2 | 22 | 22 | 22 | 21 | 25 | 24 | |

| 2½ | 31 | 31 | 31 | 25 | 32 | 31 | |

| 3 | 36 | 36 | 36 | 29 | 35 | 36 | |

| 4 | 53 | 53 | 53 | 51 | 54 | 53 | |

| 5 | 83 | 83 | 83 | 81 | 87 | 86 | |

| 6 | 110 | 110 | 110 | 105 | 115 | 110 | |

| 8 | 172 | 172 | 172 | 190 | 200 | 187 | |

| 10 | 245 | 245 | 245 | 277 | 290 | 268 | |

| 12 | 326 | 326 | 326 | 371 | 415 | 372 | |

| 14 | 400 | 400 | 400 | 415 | 520 | 562 | |

| 16 | 459 | 459 | 459 | 488 | 619 | 685 | |

| 18 | 647 | 647 | 647 | 670 | 880 | 924 | |

| 20 | 792 | 792 | 792 | 868 | 1107 | 1164 | |

| 24 | 1480 | 1480 | 1480 | 1659 | 2099 | 2107 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 1500 Flanges | ½ | 6 | 6 | 6 | 6 | 4 | 7 |

| ¾ | 6 | 6 | 6 | 6 | 6 | 7 | |

| 1 | 8 | 8 | 8 | 8 | 9 | 9 | |

| 1¼ | 10 | 10 | 10 | 10 | 10 | 10 | |

| 1½ | 14 | 14 | 14 | 14 | 14 | 14 | |

| 2 | 25 | 25 | 25 | 25 | 25 | 25 | |

| 2½ | 36 | 36 | 36 | 35 | 35 | 36 | |

| 3 | 48 | 48 | 48 | 47 | 48 | 48 | |

| 4 | 73 | 73 | 73 | 75 | 73 | 73 | |

| 5 | 132 | 132 | 132 | 140 | 140 | 132 | |

| 6 | 165 | 165 | 165 | 170 | 160 | 165 | |

| 8 | 260 | 260 | 260 | 286 | 302 | 275 | |

| 10 | 436 | 436 | 436 | 485 | 510 | 455 | |

| 12 | 667 | 667 | 667 | 749 | 775 | 690 | |

| 14 | 940 | 940 | 940 | 890 | 975 | 940 | |

| 16 | 1250 | 1250 | 1250 | 1250 | 1300 | 1250 | |

| 18 | 1625 | 1625 | 1625 | 1475 | 1750 | 1625 | |

| 20 | 2050 | 2050 | 2050 | 1775 | 2225 | 2050 | |

| 24 | 2825 | 2825 | 2825 | 2825 | 3625 | 3325 | |

| Pressure Class | Nominal Size Of Pipe (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (LOOSE) | Blind (BLRF) | Weld Neck (WNRF) |

| Class 2500 Flanges | ½ | …. | 7 | …. | 7 | 7 | 8 |

| ¾ | …. | 9 | …. | 8 | 10 | 9 | |

| 1 | …. | 12 | …. | 12 | 12 | 13 | |

| 1¼ | …. | 18 | …. | 17 | 18 | 20 | |

| 1½ | …. | 25 | …. | 24 | 25 | 28 | |

| 2 | …. | 38 | …. | 37 | 39 | 42 | |

| 2½ | …. | 55 | …. | 53 | 56 | 52 | |

| 3 | …. | 83 | …. | 80 | 86 | 94 | |

| 4 | …. | 127 | …. | 122 | 133 | 146 | |

| 5 | …. | 210 | …. | 204 | 223 | 244 | |

| 6 | …. | 323 | …. | 314 | 345 | 378 | |

| 8 | …. | 485 | …. | 471 | 533 | 576 | |

| 10 | …. | 925 | …. | 897 | 1025 | 1068 | |

| 12 | …. | 1300 | …. | 1262 | 1464 | 1608 |

Largest Inventory Of Stainless Steel 904L Flanges

- 904L Stainless Steel Nipo Flanges

- Stainless Steel 904L Pipe Flanges

- DIN 1.4539 Weldings Neck Flanges

- Stainless Steel 904L RTJ Flanges

- ASME B16.5 SS 904L Ring Type Joint Flange

- ASTM A182 Stainless Steel F904L Slip on Flanges

- UNS N08904 Raised Face Flange

- DIN 1.4539 Orifice Flange

- Stainless Steel 904L BLRF Flange

- UNS N08904 Socket Weld Flanges

- Stainless Steel 904L Reducing Flanges

- 904L PN 16 Stainless Steel Flanges

- SS 904L 150# Plate Flange

- Stainless Steel 904L PN 10 Flange

- ASTM A182 SS 904L Screwed Flanges

- 904L Stainless Steel Blind Flanges

- Stainless Steel 904L Spectacle Blind Flanges

- ASTM A182 SS F904L Threaded Flanges

- UNS N08904 Lap Joint Flanges

- UNS N08904 SORTJ Flange

- Stainless Steel 904L Tongue & Groove Flanges

- 904L Stainless Steel JIS B2220 Flange

- SS 904L Weld Neck Flanges

- ASTM A182 F904L WNRF Flanges

- DIN 1.4539 Loose Flanges

- 904L Stainless Steel Orifice Flanges

- SS 904L BS 4504 Flanges

- ANSI B16.5 Stainless Steel 904L SWRF Flanges

- UNS N08904 Ring Type Joint Flanges

- 904L Stainless Steel Flanges

- ASME SA182 F904L Flat Face Flanges

- WERKSTOFF NR. 1.4539 EN 1092-1 Flanges

- ASTM A182 Stainless Steel F904L Groove & Tongue Flange

- ASME SA182 F904L SS Long Weld Neck Flanges

- SS 904L Forged Flanges

- UNS N08904 Welding Neck Flange

- ANSI B16.5 Stainless Steel 904L Flange

- 904L Stainless Steel DN150 PN16 Flange

Manufacturing Standard / Pressure Rating of 904L SS Pipe Flanges

| ASME/ANSI B 16.5 | Blind Flange, High Hub Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Ring Type Joint Flange, Lap Joint Flange, Threaded Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Welding Neck Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Slip on Flange, Threaded Flange, Welding Neck Flange, |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange, Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange, Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

ASTM A182 SS 904L Flange Application