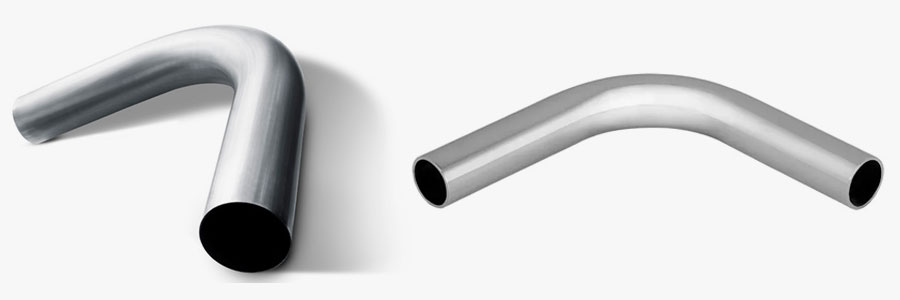

Long Radius Bend

En 10253 Long Radius Bend, SS Long Radius Bends, BS1640 Long Radius Bend, Monel ButtWeld Long Radius Bend, DIN 2615 Seamless Long Radius Bend at Best Price in India.

VM Energy Solutions INC is an acknowledged distributor and exporter of Long Radius Bend Pipe Fittings, which gives notably higher corrosion resistance that within the equal environments. Copper Nickel Long Radius Bend Pipe Fittings is regularly used at cryogenic temperatures, with extremely good sturdiness to -450 Deg F, and occasional magnetic permeability. An ideally fast cooling on this steel must be aspired entire welding as well, to keep away from the vulnerability to inter-granular corrosion and embrittlement. After uniform heating for this product as much as 2150 Deg F (1177 Deg C) maximum not unusual hot work strategies may be effectively executed. This product and its low carbon variations are used in which an excessive strength stainless steel is needed. Hardening of this steel does now no longer reply to heat remedy.

Stainless Steel Long Radius Bend Pipe Fittings resists oxidation as much as 2010 Deg F (1100 Deg C) beneath mildly cyclic conditions. It is used at temperatures as much as 1150 Deg C in non-stop carrier, and 1035 Deg C in intermittent carrier. Because of its excessive chromium and mild nickel content material, it's far proof against suffixation and also can be utilized in reasonably carburizing atmospheres. The excessive chromium and nickel contents on this steel offer similar corrosion resistance, advanced resistance to oxidation and the retention of a bigger fraction of room temperature strength than the not unusual austenitic alloys.

Inconel Extruded Long Radius Bend, Alloy Steel Long Radius Bend, Duplex Steel Long Radius Bend, Nickel Alloy Long Radius Bend, Hastelloy Long Radius Bend, ANSI B16.9 Butt weld Long Radius Bend Supplier in Mumbai, India.

Carbon Steel Long Radius Bend Pipe Fittings is commonly used for improved temperature applications as its excessive chromium and nickel content material offer strong corrosion resistance. The thinnest layer viable on this steel must be welded (stringer bead approach) due to the fact a higher cooling velocity decreases the dependency to hot cracks. By the use of fusion or resistance approach maximum of the austenitic stainless steels like this alloy may be quick welded, due to the fact oxyacetylene welding isn't always recommended. Use low aspect of variety for intermediate annealing, as it can't be hardened with the aid of using thermal remedy. It is a notably alloyed austenitic stainless steel used for excessive temperature application.

We Keep Bulk Stock Of ANSI B16.9 Long Radius Bend, Carbon Steel Long Radius Bend at Our Stockyard, Check Nickel Alloy Long Radius Bend Dimension, Buy Monel Long Radius Bend At an Affordable Price In India.

Specification Of Long Radius Bend Pipe Fittings

| Long Radius Bend Pipe Fittings size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

|---|---|

| Long Radius Bend Fitting Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Long Radius Bend Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Long Radius Bend Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| Grooved Long Radius Bend Type | DN15-DN1200 |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Long Radius Bend Fitting Fittings | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Long Radius Bend Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for Long Radius Bend |

|

| Application |

|

Long Radius Bend Standard

| Stainless Steel Long Radius Bend | ASTM A403 WP316, 316L, WP304, 304L, ASTM A182 F316L, 304L, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Alloy Steel Long Radius Bend | ASTM A234, ASME SA234 WP1, WP5, WP9, WP11, WP22, WP91 |

| Super Duplex Long Radius Bend | ASTM A815 / ASME SA815 UNS No S32750, S32950 |

| Duplex Steel Long Radius Bend | ASTM A815 / ASME SA815 UNS No S31803, S32205 |

| Nickel Alloy Long Radius Bend | ASTM B336, ASME SB336, Nickel 200 (UNS N02200), Nickel 201 (UNS N02201), Monel 400 (UNS N04400), Monel 500 (UNS N05500), Inconel 800 (UNS N08800), Inconel 825 (UNS N08825), Inconel 600 (UNS N06600), Inconel 625 (UNS N06625), Inconel 601 (UNS N06601), Hastelloy C 276 (UNS N10276), Titanium (Grade I & II), Alloy 20 (UNS N08020), Cupro Nickel 70/30, CuNi30Mn1Fe, CuNi10Fe1Mn. |

| Carbon Steel Long Radius Bend | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Long Radius Bend | ASTM A420 WPL3, A420 WPL6 |

Bulk Stock of ASME B16.9 Buttweld Long Radius Bend, Rate of SS Long Radius Bend in India, Check Online Alloy Steel Long Radius Bend Pressure Ratings, Largest Inconel Long Radius Bend Stockist in India, We offer ANSI B16.9 Long Radius Bend in almost all Sizes.

Largest Inventory Of Long Radius Bend

- ASME B 16.9 Buttweld Long Radius Bend Manufacturer

- ASME B16.9 Hastelloy Long Radius Bend

- Inconel Butt weld Long Radius Bend Exporter

- ASME B16.9 Buttweld Long Radius Bend

- Alloy Steel Buttweld Long Radius Bend

- Nickel Alloy Long Radius Bend Stockist

- Buttweld Grooved Long Radius Bend

- Monel Buttweld Long Radius Bend

- DIN 2615 Long Radius Bend

- Stainless Steel Long Radius Bend Fitting Sch 40

- Stainless Steel Long Radius Bend Pipe Fitting

- ASME B16.9 Long Radius Bend Fitting SCH 10

- BS1640 Long Radius Bend

- Carbon Steel Long Radius Bend

- Titanium Buttweld Long Radius Bend Supplier

- Brass Long Radius Bend

- Stainless Steel Long Radius Bend

- 254 SMO Buttweld Long Radius Bend

- Super Duplex 2507 Butt weld Long Radius Bend

- 254 SMO Long Radius Bend

- DIN 2615 Extruded Long Radius Bend Dimensions

- MSS SP43 Galvanised Long Radius Bend

- Buttweld Long Radius Bend

- Carbon Steel Long Radius Bend Pipe Fitting Sch 80

- Duplex Steel 2205 Long Radius Bend

- High Nickel Alloy Long Radius Bend

Long Radius Bend Application