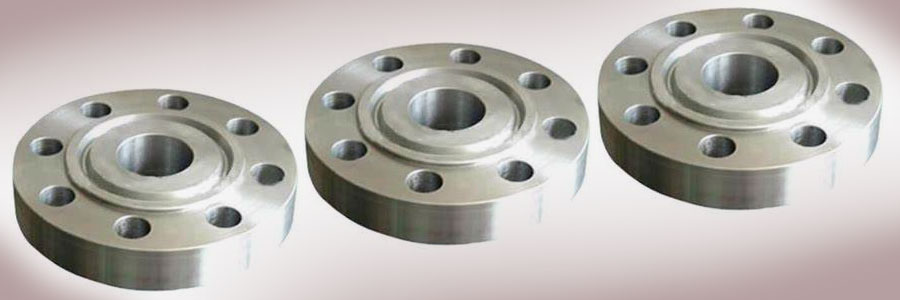

Ring Type Joint Flanges

- Home

- Flanges

ANSI B16.5 Ring Type Joint Flanges, RTJ Raised Face Flanges, EN1092-1 Ring Type Joint Flanges, API 6A RTJ Flanges at Best Price in India.

VM Energy Solutions INC is an acknowledged exporter and stockist of Ring Type Joint Pipe Flanges, which has fantastic fatigue strength and pressure-corrosion cracking resistance to chloride ions. The incredible strength and durability of this Titanium Ring Type Joint Flanges within the temperature variety cryogenic to 2000 Degree F (1093 Degree C) are derived typically from the solid solution outcomes of the refractory metals, columbium and molybdenum, in a nickel-chromium matrix. The strength of this product is typically a solid solution impact from molybdenum and columbium. It additionally has fantastic corrosion resistance to many acids and resists intergranular assault and pressure-corrosion cracking. Our technology for this alloy efficiently trims down the rigidity of the weld, in both - fusion zone and heat-affected zone.

Because of its resistance to corrosion, strain and heat, this Copper Nickel Ring Type Joint Flanges is good for applications within the electricity industry, aerospace, and chemical processing additives and hardware and marine industries. Strength of this product is derived from the stiffening impact of molybdenum and niobium on its nickel-chromium matrix; accordingly precipitation-hardening remedies aren't required. The ability to face up to excessive pressure and an extensive variety of temperatures of this product, each inside and outside of water. It is a good shaped tool that has varied openings in it, and are getting used to alter the manner of pipe directions.

DIN-PN16 Steel Ring Type Joint Flanges, API 6A RTJ Flanges, JIS 5K Ring Type Joint Flanges, Duplex Steel Raised Face RTJ Flanges, Stainless Steel Ring Type Joint Flanges, Carbon Steel RTJ Flanges, Check BS1560 Ring Type Joint Supplier in Mumbai, India.

Alloy 20 Ring Type Joint Flanges is likewise Suitable for pressurized applications, Allow extrude in course of glide, Can maintain excessive temperature, Dimensional stability, Inert to all chemicals, acids and solvents, and more. They are used for numerous industries inclusive of in Chemical industry, Water supply, Petrochemical industry, Food & beverage industry, Pharmaceutical industry, Oil field, Power plants, and more. The principal feature of this steel is to allow the course at a certain degree to the main glide, in which the real course passes for the duration of the ‘run’. Furthermore, they may be used for department institutions in its irrigation structures, in which horizontal and one vertical pipe may be results easily attached.

We Keep Bulk Stock Of Ring Type Joint Flanges, MSS SP-44 RTJ Flanges at Our Stockyard, Check Nickel Alloy Ring Type Joint Flanges Dimension, Buy Inconel Raised Face Ring Type Joint Flanges at an Affordable Price In India.

Ring Type Joint Flanges Standard Specification

| ASME B16.5 ANSI B16.5 Class 150 Ring Type Joint Flanges Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| ANSI B16.5 Class 150 Ring Type Joint Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ASME Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ASME B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| ANSI B16.5 Class 150 Ring Type Joint Flanges Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| ANSI B16.5 Class 150 Ring Type Joint Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of ANSI B16.5 Class 150 Ring Type Joint Flanges | Forged / Ring Type Joint / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of | ASME DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| ANSI B16.5 Class 150 Ring Type Joint Flanges Uses & application |

|

Ring Type Joint Flanges Standard

| Stainless Steel ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Carbon Steel ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Alloy Steel ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper Nickel ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Inconel ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 ANSI B16.5 Class 150 Ring Type Joint Flanges |

| Hastelloy ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Nickel ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex ANSI B16.5 Class 150 Ring Type Joint Flanges | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex ANSI B16.5 Class 150 Ring Type Joint Flanges | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy ANSI B16.5 Class 150 Ring Type Joint Flanges | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

Bulk Stock of ASTM A182 F304 2500 Lb Ring Type Joint Flanges, Rate of SS Ring Type Joint in India, Check online Alloy Steel RTJ Flange Pressure Ratings, Largest Raised Face Ring Type Joint Flanges Stockist in India, We offer ANSI B16.5 RTJ Flange in almost all Sizes.

Material Grades Of Ring Type Joint Flanges

| Stainless Steel Ring Type Joint Flanges | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Carbon Steel Ring Type Joint Flanges | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Alloy Steel Ring Type Joint Flanges | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium Ring Type Joint Flanges | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper Ring Type Joint Flanges | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel Ring Type Joint Flanges | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Inconel Ring Type Joint Flanges | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 ANSI B16.5 Class 150 Ring Type Joint Flanges |

| Hastelloy Ring Type Joint Flanges | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel Ring Type Joint Flanges | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 Ring Type Joint Flanges | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium Ring Type Joint Flanges | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel Alloy Ring Type Joint Flanges | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex Steel Ring Type Joint Flanges | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex Ring Type Joint Flanges | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy Ring Type Joint Flanges | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

| 254 SMO Ring Type Joint Flanges | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic Ring Type Joint Flanges | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Brass Ring Type Joint Flanges | 3602 / 2604 / H59 / H62 / etc. |

| Other Ring Type Joint Flanges material | Tin bronze, Alumunum bronze, Lead bronze |

Dimensions of Ring Type Joint Flanges

| ANSI/ASME/ASA B16.5 150lb/sq.in. Flanges SO-RF | ||||||||||

| ø | D | b | g | m | J | h | k | Holes | l | Kg. |

| 1/2" | 88,9 | 11,1 | 34,9 | 30,2 | 22,3 | 15,9 | 60,3 | 4 | 15,9 | 0,400 |

| 3/4" | 98,4 | 12,7 | 42,9 | 38,1 | 27,7 | 15,9 | 69,8 | 4 | 15,9 | 0,700 |

| 1" | 107,9 | 14,3 | 50,8 | 49,2 | 34,5 | 17,5 | 79,4 | 4 | 15,9 | 0,800 |

| 1 1/4" | 117,5 | 15,9 | 63,5 | 58,8 | 43,2 | 20,6 | 88,9 | 4 | 15,9 | 1,100 |

| 1 1/2" | 127,0 | 17,5 | 73,0 | 65,1 | 49,5 | 22,2 | 98,4 | 4 | 15,9 | 1,400 |

| 2" | 152,4 | 19,0 | 92,1 | 77,8 | 62,0 | 25,4 | 120,6 | 4 | 19,0 | 2,200 |

| 2 1/2" | 177,8 | 22,2 | 104,8 | 90,5 | 74,7 | 28,6 | 139,7 | 4 | 19,0 | 3,600 |

| 3" | 190,5 | 23,8 | 127,0 | 107,9 | 90,7 | 30,2 | 152,4 | 4 | 19,0 | 4,100 |

| 3 1/2" | 215,9 | 23,8 | 139,7 | 122,2 | 103,4 | 31,7 | 177,8 | 8 | 19,0 | 5,200 |

| 4" | 228,6 | 23,8 | 157,2 | 134,9 | 116,1 | 33,3 | 190,5 | 8 | 19,0 | 5,600 |

| 5" | 254,0 | 23,8 | 185,7 | 163,6 | 143,8 | 36,5 | 215,9 | 8 | 22,2 | 6,300 |

| 6" | 279,4 | 25,4 | 215,9 | 192,1 | 170,7 | 39,7 | 241,3 | 8 | 22,2 | 7,500 |

| 8" | 342,9 | 28,6 | 269,9 | 246,1 | 221,5 | 44,4 | 298,4 | 8 | 22,2 | 12,600 |

| 10" | 406,4 | 30,2 | 323,8 | 304,8 | 276,3 | 49,2 | 361,9 | 12 | 25,4 | 18,500 |

| 12" | 482,6 | 31,7 | 381,0 | 365,1 | 327,1 | 55,6 | 431,8 | 12 | 25,5 | 28,000 |

| 14" | 533,4 | 34,9 | 412,7 | 400,0 | 359,1 | 57,1 | 476,2 | 12 | 28,6 | 36,000 |

| 16" | 596,9 | 36,5 | 469,9 | 457,2 | 410,5 | 63,5 | 539,7 | 16 | 28,6 | 46,000 |

| 18" | 635,0 | 39,7 | 533,4 | 504,8 | 461,8 | 68,3 | 577,8 | 16 | 31,7 | 50,000 |

| 20" | 698,5 | 42,9 | 584,2 | 558,8 | 513,1 | 73,0 | 635,0 | 20 | 31,7 | 64,000 |

| 22" | 749,3 | 46,0 | 641,2 | 609,6 | 564,4 | 79,4 | 692,1 | 20 | 34,9 | 72,000 |

| 24" | 812,8 | 47,6 | 692,1 | 663,6 | 615,9 | 82,5 | 749,3 | 20 | 34,9 | 89,000 |

| ANSI/ASME/ASA B16.5 600lb/sq.in. Flanges WN-RF | ||||||||||

| ø | D | b | g | m | J | h | k | Holes | l | Kg. |

| 1/2" | 95,2 | 14,3 | 34,9 | 38,1 | 22,3 | 22,2 | 66,7 | 4 | 15,9 | 0,800 |

| 3/4" | 117,5 | 15,9 | 42,9 | 47,6 | 27,7 | 25,4 | 82,5 | 4 | 19,0 | 1,400 |

| 1" | 123,8 | 17,5 | 50,8 | 54,0 | 34,5 | 27,0 | 88,9 | 4 | 19,0 | 1,600 |

| 1 1/4" | 133,3 | 20,6 | 63,5 | 63,5 | 43,2 | 28,6 | 98,4 | 4 | 19,0 | 2,100 |

| 1 1/2" | 155,6 | 22,2 | 73,0 | 69,8 | 49,5 | 31,7 | 114,3 | 4 | 22,2 | 3,100 |

| 2" | 165,1 | 25,4 | 92,1 | 84,1 | 62,0 | 36,5 | 127,0 | 8 | 19,0 | 3,700 |

| 2 1/2" | 190,5 | 28,6 | 104,8 | 100,0 | 74,7 | 41,3 | 149,2 | 8 | 22,2 | 5,400 |

| 3" | 209,5 | 31,7 | 127,0 | 117,5 | 90,7 | 46,0 | 168,3 | 8 | 22,2 | 7,300 |

| 3 1/2" | 228,6 | 34,9 | 139,7 | 133,3 | 103,4 | 49,2 | 184,1 | 8 | 25,4 | 8,900 |

| 4" | 273,0 | 38,1 | 157,2 | 152,4 | 116,1 | 54,0 | 215,9 | 8 | 25,4 | 11,800 |

| 5" | 330,2 | 44,4 | 185,7 | 188,9 | 143,8 | 60,3 | 266,7 | 8 | 28,6 | 24,500 |

| 6" | 355,6 | 47,6 | 215,9 | 222,2 | 170,7 | 66,7 | 292,1 | 12 | 28,6 | 29,500 |

| 8" | 419,1 | 55,6 | 269,9 | 273,0 | 221,5 | 76,2 | 349,2 | 12 | 31,7 | 43,000 |

| 10" | 508,0 | 63,5 | 323,8 | 342,8 | 276,3 | 85,7 | 431,8 | 16 | 34,9 | 70,000 |

| 12" | 558,8 | 66,7 | 381,0 | 400,0 | 327,1 | 92,1 | 488,9 | 20 | 34,9 | 86,000 |

| 14" | 603,2 | 69,8 | 412,7 | 431,8 | 359,1 | 93,7 | 527,0 | 20 | 38,1 | 100,000 |

| 16" | 685,8 | 76,2 | 469,9 | 495,3 | 410,5 | 106,4 | 603,2 | 20 | 41,3 | 142,000 |

| 18" | 742,9 | 82,5 | 533,4 | 546,1 | 461,8 | 117,5 | 654,0 | 20 | 44,4 | 175,000 |

| 20" | 812,8 | 88,9 | 584,2 | 609,6 | 513,1 | 127,0 | 723,9 | 24 | 44,4 | 232,000 |

| 22" | 869,9 | 95,2 | 641,2 | 666,7 | 564,4 | 133,3 | 777,9 | 24 | 47,6 | 292,000 |

| 24" | 939,8 | 101,6 | 692,1 | 717,5 | 615,9 | 139,7 | 838,2 | 24 | 50,8 | 330,000 |

ASME B16.5 Ring Type Joint Flange Weight Chart

| Rated Diameter | O.D. of Pipe | Flange Parameter | Neck Size | Size of R.F. | Bolts | Approx. Weight | |||||||

| DN | d1 | D | d5 | b | k | h | d3 | r | d4 | f | No. of holes |

d2 | KG |

| 10 | 17.2 | 90 | 17.7 | 14 | 60 | 20 | 30 | 4 | 40 | 2 | 4 | 14 | 0.56 |

| 15 | 21.3 | 95 | 22 | 14 | 65 | 20 | 35 | 4 | 45 | 2 | 4 | 14 | 0.62 |

| 20 | 26.9 | 105 | 27.6 | 16 | 75 | 24 | 45 | 4 | 58 | 2 | 4 | 14 | 0.91 |

| 25 | 33.7 | 115 | 34.4 | 16 | 85 | 24 | 52 | 5 | 68 | 2 | 4 | 14 | 1.09 |

| 32 | 42.4 | 140 | 43.1 | 16 | 100 | 26 | 60 | 5 | 78 | 2 | 4 | 18 | 1.58 |

| 40 | 48.3 | 150 | 49 | 16 | 110 | 26 | 70 | 5 | 88 | 3 | 4 | 18 | 1.76 |

| 50 | 60.3 | 165 | 61.1 | 18 | 125 | 28 | 85 | 5 | 102 | 3 | 4 | 18 | 2.39 |

| 65 | 76.1 | 185 | 77.1 | 18 | 145 | 32 | 105 | 5 | 122 | 3 | 4 | 18 | 3.1 |

| 80 | 88.9 | 200 | 90.3 | 20 | 160 | 34 | 118 | 5 | 138 | 3 | 8 | 18 | 3.77 |

| 100 | 114.3 | 220 | 115.9 | 20 | 180 | 38 | 140 | 5 | 158 | 3 | 8 | 18 | 4.29 |

| 125 | 139.7 | 250 | 141.6 | 22 | 210 | 40 | 168 | 5 | 188 | 3 | 8 | 18 | 5.86 |

| 150 | 168.3 | 285 | 170.5 | 22 | 240 | 44 | 196 | 5 | 212 | 3 | 8 | 22 | 7.22 |

| 175 | 193.7 | 315 | 196.1 | 24 | 270 | 44 | 224 | 6 | 242 | 3 | 8 | 22 | 9.18 |

| 200 | 219.4 | 340 | 222 | 24 | 295 | 44 | 247 | 6 | 268 | 3 | 8 | 22 | 9.95 |

| 250 | 273 | 395 | 276 | 26 | 350 | 46 | 300 | 6 | 320 | 3 | 12 | 22 | 12.69 |

| 300 | 323.9 | 445 | 327 | 26 | 400 | 46 | 352 | 6 | 370 | 4 | 12 | 22 | 14.4 |

| 350 | 355.6 | 505 | 359 | 26 | 460 | 53 | 398 | 10 | 430 | 4 | 16 | 22 | 22.36 |

| 400 | 406.4 | 565 | 410 | 26 | 515 | 57 | 448 | 10 | 482 | 4 | 16 | 26 | 26.85 |

| 450 | 457 | 615 | 461 | 28 | 565 | 62 | 502 | 10 | 532 | 4 | 20 | 26 | 32.53 |

| 500 | 508 | 670 | 512 | 28 | 620 | 67 | 552 | 10 | 585 | 4 | 20 | 26 | 37.84 |

| 600 | 610 | 780 | 614 | 28 | 725 | 75 | 658 | 10 | 685 | 5 | 20 | 30 | 49.32 |

| 700 | 711 | 895 | 716 | 30 | 840 | 77 | 760 | 10 | 800 | 5 | 24 | 30 | 63.86 |

| 800 | 813 | 1015 | 818 | 32 | 950 | 84 | 864 | 10 | 905 | 5 | 24 | 33 | 85.19 |

| 900 | 914 | 1115 | 920 | 34 | 1050 | 88 | 969 | 10 | 1005 | 5 | 28 | 33 | 101.4 |

| 1000 | 1016 | 1230 | 1022 | 34 | 1160 | 92 | 1071 | 10 | 1110 | 5 | 28 | 36 | 119.7 |

Largest Inventory Of Ring Type Joint Flange

- Ring Type Joint 8 Inch Flanges

- ANSI B16.5 RTJ Plate Flanges

- BS4504 PN16 Ring Type Joint Flange

- Hastelloy Ring Type Joint Flanges

- Alloy 20 Ring Type Joint Plate Flanges

- Brass Ring Type Joint Flange

- ANSI B16.5 RTJ Raised Face Flanges

- DN150 class 150 6 Inch Ring Type Joint Flange

- Copper Nickel SORF Supplier

- 254 SMO Ring Type Joint Flange

- ASME B16.5 Ring Type Joint Flange Stockist

- Ring Type Joint Plate Flanges Exporter

- RTJ Flanges Manufacturer

- DIN Standard PN25 RTJ Flanges

- DIN Standard Pn25 Ring Type Joint Plate Flange

- JIS B2220 SS400 16 Inch RTJ Flat Face Flange

- Raised Face Ring Type Joint Flanges

- ASME B16.5 Inconel Ring Type Joint Flanges

- 150 lb 316L RTJ Raised Face Flange

- JIS 10K Ring Type Joint Flange

- Dn100 Pn16 Ring Type Joint Flange

- ASME B16.5 Hastelloy RTJ Raised Face Flanges

- 600 Lb Ring Type Joint Flange Dimensions

- Din 2501 300# Ring Type Joint Flange Dimensions

- PN16/3 Ring Type Joint Flanges

- Duplex Steel 2205 Ring Type Joint Flange

- EN 1092-1 Ring Type Joint Flange

- Alloy 20 RTJ Plate Flanges Price List

- Class 150 Ring Type Joint Plate Flanges

- Gasket For Ring Type Joint Flange

- Copper Nickel RTJ Flanges

- High Nickel Alloy Ring Type Joint Flanges

- Stainless Steel RTJ Flanges

- Titanium Ring Type Joint Flange

- Awwa C207 Class D Ring Type Joint Flange

- High Nickel Alloy Series A and B RTJ Flange

- ANSI #150 Ring Type Joint Flanges

- BS4504 Large Diameter RTJ Flange

Ring Type Joint Flange Application