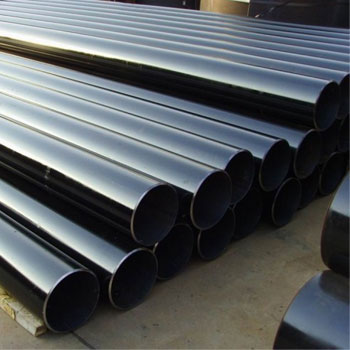

Carbon Steel EFW/HFW Pipe & Tubes

- Home

- Carbon Steel

ASME SA671 Electropolished EFW Pipes, ASTM A671 Carbon Steel HFW Pipe, Carbon Steel ASTM A671 Square Electric Fusion Welded Pipe, Carbon Steel A671 HFW Pipe at Best Price in India.

VM Energy Solutions INC is a famous distributor and manufacturer of Carbon Steel EFW Pipes & Carbon Steel HFW Pipes, which are more proof against atmospheric and different moderate sorts of corrosion than other steels. CS EFW Pipes is likewise utilized in industries generating paper and pulp, and as condensers in electricity stations the use of fossil and nuclear fuels. It is as well utilized in engineering and shipbuilding, chemical & Fertilizer production, for onshore & offshore industries, surgical instruments, fasteners, etc. It acts as a lubricant all through patron component forming operation. It is evolved in general to resist more correctly the assault of sulphurous acid compounds. For surest corrosion resistance, CS HFW Pipes must be annealed after forging. It is utilized in Chemical, Food processing, Petrochemical, Pharmaceutical, Power technology, Pulp and Paper, etc. It has exact oxidation resistance in non-stop provider to 925 Degree C and in intermittent provider to 879 Degree C. Any cold working operations will growth the strength and hardness of this alloy and can go away it barely magnetic.

Carbon Steel Electric Fusion Welded Pipes also are appropriate for vertical groups for boiler units, strength technology plants, heat exchangers units, oil and gas exploration, creation industry, etc. The low carbon content material of this steel offers immunity to inter-granular corrosion in applications wherein heavy move sections cannot be annealed after welding or wherein low temperature pressure relieving remedies are preferred. It is used for strength technology along with fossil fuels and nuclear, flue gas desulfurization systems, etc.

High Quality A671 Carbon Steel Electric Fusion Welded Pipe, ASME SA671 High Pressure HFW Pipe, CS A671 EFW Pipe, ASME SA671 High Pressure HFW Pipe, ASTM A671 Carbon Steel EFW Pipes Supplier in Mumbai, India.

Low speeds and consistent feeds will limit the tendency of this Carbon Steel High Frequency Welded Pipes to work harden. Because of its benefits and chemical composition, it's miles used appreciably in quite a few industries for many applications. It additionally discover many makes use of within the brewery and different beverage industries, pharmaceutical and bioprocessing industries. All not unusual fusion and resistance strategies for this alloy besides oxyacetylene welding have demonstrated successful. It might also additionally reason precipitates of secondary stages within the weld metallic.

We Keep Bulk Stock Of ASTM A671 GRADE CC 70 PIPES, A671 GRADE CARBON 65 WELDED PIPES at Our Stockyard, ASTM A671 Carbon Steel EFW Pipe Dimension, Buy CS A671 HFW Pipe at an Affordable Price In India.

Carbon Steel EFW/HFW Pipe & Tubes Standard Specification

| Grade | ASME SA671 / ASTM A671 GRADE CA55, CB60, CB65, VB70, VV60, VV65, VV70, CD70, CD80, CE55, CE60, CF65, CF70, CF66, CF71, CG100, CH100, CJ101, CJ102, CJ103, CJ104, CJ105, CJ106, CJ107, CJ108, CJ109, CJ110, CJ111, CJ112, CJ113, CK75, CP65, CP75,

ASME SA672 / ASTM A672 GRADE A45, A50, A55, B55, B60, B65, B70, C55,C60, C65, C70, D70, D80, E55, E60, H75, H80, J80, J90, J100, K75, K85, L65, L70, L75, N75 |

| Standard | ASTM A671, ASME SA671 |

| Outer Diameter Size | 16"NB To 100"NB |

| Form | Round, Square, Rectangular, Hydraulic Etc |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Length | Single Random, Double Random & Cut Length. |

| Type | EFW Pipe / Electric Fusion Welded Pipe |

| End | Plain End, Beveled End, Coupling |

ASTM A671 EFW Pipes Class Designation

| Class | Heat Treatment on Pipe | Radiography, see Section | Pressure Test, see: |

| A671 Pipe Class 10 | none | none | none |

| A671 Pipe Class 11 | none | 9 | none |

| A671 Pipe Class 12 | none | 9 | 8.3 |

| A671 Pipe Class 13 | none | none | 8.3 |

| A671 Pipe Class 20 | stress relieved, see 5.3.1 | none | none |

| A671 Pipe Class 21 | stress relieved, see 5.3.1 | 9 | none |

| A671 Pipe Class 22 | stress relieved, see 5.3.1 | 9 | 8.3 |

| A671 Pipe Class 23 | stress relieved, see 5.3.1 | none | 8.3 |

| A671 Pipe Class 30 | normalized, see 5.3.2 | none | none |

| A671 Pipe Class 31 | normalized, see 5.3.2 | 9 | none |

| A671 Pipe Class 32 | normalized, see 5.3.2 | 9 | 8.3 |

| A671 Pipe Class 33 | normalized, see 5.3.2 | none | 8.3 |

| A671 Pipe Class 40 | normalized and tempered, see 5.3.3 | none | none |

| A671 Pipe Class 41 | normalized and tempered, see 5.3.3 | 9 | none |

| A671 Pipe Class 42 | normalized and tempered, see 5.3.3 | 9 | 8.3 |

| A671 Pipe Class 43 | normalized and tempered, see 5.3.3 | none | 8.3 |

| A671 Pipe Class 50 | quenched and tempered, see 5.3.4 | none | none |

| A671 Pipe Class 51 | quenched and tempered, see 5.3.4 | 9 | none |

| A671 Pipe Class 52 | quenched and tempered, see 5.3.4 | 9 | 8.3 |

| A671 Pipe Class 53 | quenched and tempered, see 5.3.4 | none | 8.3 |

| A671 Pipe Class 70 | quenched and precipitation heat treated | none | none |

| A671 Pipe Class 71 | quenched and precipitation heat treated | 9 | none |

| A671 Pipe Class 72 | quenched and precipitation heat treated | 9 | 8.3 |

| A671 Pipe Class 73 | quenched and precipitation heat treated | none | 8.3 |

Different Forms of Carbon Steel EFW/HFW Pipe & Tubes

Carbon Steel Seamless Pipe

Carbon Steel Welded Pipe

Carbon Steel EFW Pipe

Carbon Steel ERW Pipe

Carbon Steel Tubes

Carbon Steel Square Pipe

Carbon Steel Hollow Pipe

Bulk Stock of ASTM A671 Carbon Steel HFW Pipe, Rate of Carbon Steel ASTM A671 Square Electric Fusion Welded Pipe in India, Check online CS ELECTRIC-FUSION WELDED PIPE Pressure Ratings, Largest Carbon Steel EFW Pipes Stockist in India, We offer CS HFW Pipes in almost all Sizes.

ASTM A671 EFW Pipes Plate Specification

| Pipe Grade | Type of Steel | ASTM Specification | |

| No. | Grade | ||

| ASTM A671 CA 55 Pipe | plain carbon | A285 / A285M | C |

| ASTM A671 CB 60 Pipe | plain carbon, killed | A515 / A515M | 60 |

| ASTM A671 CB 65 Pipe | plain carbon, killed | A515 / A515M | 65 |

| ASTM A671 CB 70 Pipe | plain carbon, killed | A515 / A515M | 70 |

| ASTM A671 CC 60 Pipe | plain carbon, killed, fine grain | A516 / A516M | 60 |

| ASTM A671 CC 65 Pipe | plain carbon, killed, fine grain | A516 / A516M | 65 |

| ASTM A671 CC 70 Pipe | plain carbon, killed, fine grain | A516 / A516M | 70 |

| ASTM A671 CD 70 Pipe | manganese-silicon, normalized | A537 / A537M | 1 |

| ASTM A671 CD 80 Pipe | manganese-silicon, quenced and tempered | A537 / A537M | 2 |

| ASTM A671 CE 55 Pipe | plain carbon | A442 / A442M | 55 |

| ASTM A671 CE 60 Pipe | plain carbon | A442 / A442M | 60 |

| ASTM A671 CF 65 Pipe | nickel steel | A203 / A203M | A |

| ASTM A671 CF 70 Pipe | nickel steel | A203 / A203M | B |

| ASTM A671 CF 66 Pipe | nickel steel | A203 / A203M | D |

| ASTM A671 CF 71 Pipe | nickel steel | A203 / A203M | E |

| ASTM A671 CG 100 Pipe | 9% nickel | A353 / A353M | |

| ASTM A671 CH 100 Pipe | 9% nickel | A553 / A53M | 1 |

| ASTM A671 CJ 101 Pipe | alloy steel, quenced and tempered | A517 / A517M | A |

| ASTM A671 CJ 102 Pipe | alloy steel, quenced and tempered | A517 / A517M | B |

| ASTM A671 CJ 103 Pipe | alloy steel, quenced and tempered | A517 / A517M | C |

| ASTM A671 CJ 104 Pipe | alloy steel, quenced and tempered | A517 / A517M | D |

| ASTM A671 CJ 105 Pipe | alloy steel, quenced and tempered | A517 / A517M | E |

| ASTM A671 CJ 106 Pipe | alloy steel, quenced and tempered | A517 / A517M | F |

| ASTM A671 CJ 107 Pipe | alloy steel, quenced and tempered | A517 / A517M | G |

| ASTM A671 CJ 108 Pipe | alloy steel, quenced and tempered | A517 / A517M | H |

| ASTM A671 CJ 109 Pipe | alloy steel, quenced and tempered | A517 / A517M | J |

| ASTM A671 CJ 110 Pipe | alloy steel, quenced and tempered | A517 / A517M | K |

| ASTM A671 CJ 111 Pipe | alloy steel, quenced and tempered | A517 / A517M | L |

| ASTM A671 CJ 112 Pipe | alloy steel, quenced and tempered | A517 / A517M | M |

| ASTM A671 CJ 113 Pipe | alloy steel, quenced and tempered | A517 / A517M | P |

| ASTM A671 CK 75 Pipe | carbon-manganese-silicon | A299 / A299M | |

| ASTM A671 CP 65 Pipe | alloy steel, age hardening, normalized and preciotation heat treated | A736 / A736M | 2 |

| ASTM A671 CP 75 Pipe | alloy steel, age hardening, quenched and preciotation heat treated | A736 / A736 | 3 |

| Acceptance Criteria Charpy V-Notch | Specification and Grade | Test Temperature, °C for plate Thickness (Unless Otherwise Agreed Upon) | |||||

| Energy Absorption | |||||||

| ClassA | Min. Avg for 3 SpecimenB | Min For 1 SpecimenB | 25 mm and under | Over 25 mm to 50 mm, incl | Over 50 mm to 75 mm, incl | Over 75 mm to 125 mm, incl | |

| J | J | ||||||

| I | 14 | 10 | A285 Grade A | +4 | +16 | -- | -- |

| A285 Grade B | +10 | +21 | -- | -- | |||

| A285 Grade C | +16 | +27 | -- | -- | |||

| II | 18 | 14 | A455 | -4 | -- | -- | -- |

| III | 18 | 14 | A203 Grade A | -68 | -68 | -60 | -- |

| A203 Grade D | -101 | -101 | -87 | -- | |||

| A516 Grade 55 | -51 | -51 | -46 | -46 | |||

| A516 Grade 60 | -51 | -46 | -46 | -46 | |||

| A516 Grade 65 | -51 | -56 | -40 | -32 | |||

| IV | 20 | 16 | A203 Grade B | -68 | -68 | -60 | -- |

| A203 Grade E | -101 | -101 | -87 | -- | |||

| A203 Grade F (100 mm max) | -- | -- | -107 | -107 | |||

| A516 Grade 70 | -46 | -40 | -35 | -29 | |||

| A537 Class 1 (64 mm max) | -62 | -60 | -60 | -- | |||

| A537 Class 2 (Over 64-100 mm) | |||||||

| V | 27 | 20 | A203 Grade F | -107 | -107 | -- | -- |

| Lateral Expansion mm, Minimum Each Specimen Transverse Test | |||||||

| VI | 0.38 | A353 | -196 | -196 | -- | -- | |

| A553 Type I | -196 | -196 | -- | -- | |||

| A553 Type II | -170 | -170 | -- | -- | |||

| A517 all (64 mm max thickness) | C | C | -- | -- | |||

Largest Inventory Of Carbon Steel EFW/HFW Pipe & Tubes

- CS A671 HFW Pipes

- ASME SA671 Carbon Steel EFW Pipe

- Carbon A671 EFW Pipes

- ASME SA671 Carbon HFW Pipe

- A671 CS Polished EFW Pipe

- ASTM A671 CS Round HFW Pipe

- CS A671 HFW Pipes

- ASME SA671 CS EFW Pipe

- ASTM A671 HFW Pipe

- ASTM A671 Carbon Steel EFW Pipes

Carbon Steel EFW/HFW Pipe & Tubes Application